So many things going on here at Fishy Filaments HQ that its time for a general update.

Two massive things happened recently that will help us gain global recognition for our business model;

We won the 3D Printing Industry News award for ‘Sustainability in Additive Manufacturing’ in a global public vote and we’ve been asked to be part of an important new academic consortium – the SuMMER CDT or ‘The Centre for Doctoral Training in Sustainable Management of UK Marine Resources’.

3D Printing Industry News award for ‘Sustainability in Additive Manufacturing’ sponsored by TÜV SÜD

It was a surprise to be nominated and shortlisted, and after a public vote that saw over 140,000 votes cast across all categories, it was both a surprise and honour to win the sustainability category sponsored by TÜV SÜD by just 66 votes, beating global giants like Siemens, EOS and Desktop Metal. My flabber was never so ghasted 🙂 but I guess having nearly 1000 engaged shareholders doesn’t hurt !

It was a surprise to be nominated and shortlisted, and after a public vote that saw over 140,000 votes cast across all categories, it was both a surprise and honour to win the sustainability category sponsored by TÜV SÜD by just 66 votes, beating global giants like Siemens, EOS and Desktop Metal. My flabber was never so ghasted 🙂 but I guess having nearly 1000 engaged shareholders doesn’t hurt !

The awards were announced online (for obvious reasons) and I was proud to pick the company’s new trophy from 3D Printing Industry News at the world’s largest 3D printing trade show, Formnext, in Frankfurt, Germany.

This is a huge win for us. Its the biggest public validation of what we are doing (so far) and demonstrates without any space for question that the 3D printing industry sees value and a future for what we are doing and how.

This is a period of change for 3D printing (or Additive Manufacturing as it is more often called within industry) and to see a disruptive model such as ours at the head of the table is new, even for such an innovative industry.

Only a couple of years ago few of the larger industry players would have passed much of a comment on sustainability within their sector, so it was especially gratifying to see so many of them now have explicit statements on both their own activities and those within their supply chain. And it was great to hear from the event organisers that the lecture and discussion sessions on sustainability were the best attended throughout the 3 days of the Formnext show, including our friends at 3D Printing Cornwall who spoke passionately on their work with us and other sector participants to promote local circularity.

The Centre for Doctoral Training in Sustainable Management of UK Marine Resources

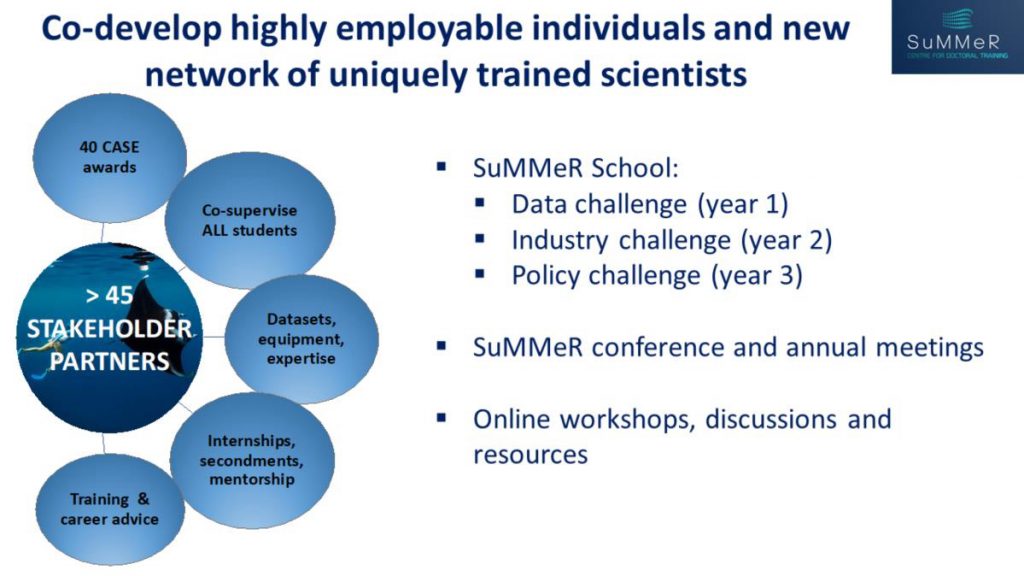

Being part of the SuMMeR CDT isn’t a typical move for a disruptive start-up. Its more the kind of thing that industry titans like Rolls Royce or Fugro take on so that they have access to talented individuals and the next generation of leaders. Both are included in this consortium alongside more local friends FishTek Marine and a number of marine consultancies.

We’re contributing our resources to this consortium for other reasons too. We believe that so little attention has been paid to the marine economy and environment over the last century, both in the UK and globally, that our political and business leaders just don’t understand how important it now is to the human race. With no voters to woo on the high seas its been a case of ‘out of sight, out of mind’ for so long that it has taken the issue of climate change to get the wet 70% of the planet on an agenda that has a full and rounded context.

Fishy Filaments is not a campaigning organisation but we are a business built for ‘impact’, primarily on carbon emissions. So we have a challenge in how we present our mission to the world without being too prescriptive or exclusive of alternate viewpoints, whilst at the same time being a business run for profit.

For us that’s a challenge, but its not a conflict. If fishing net recycling is to become the first choice for all fishers, everywhere, it has to pay for itself and to fit the fishing sector’s needs and motivations. It will be a service to the fishing industry, but that doesn’t mean we can’t design our activities to be the best they can be to everyone and everything else too. And that starts with our customers for the recycled materials we produce but also, and maybe more importantly, the recycling hardware we design.

This is the area where we expect this new research centre will help us – providing the step-out and 360° view of our operations and the wider social, legal, environmental and policy landscape we expect to be working in as we grow. It is not primarily a technology partnership as we already lead there.

The SuMMeR CDT is a means to extend and strengthen the data set around our products and services through sponsorship of CASE students (industry focussed PhD research) who will have world-leading support from some of the most dedicated marine specialist academics and practitioners, and to spread a general appreciation of the practical and technological issues that define real world execution of our ideas through wider interactions with students outside of specific projects.

But more than the simple growth of IP this consortium is a force multiplier for our shareholder’s impact investment, a way to meet the next generation of maritime leaders on common ground and help them see outside academic silos to coastal communities where interdisciplinarity isn’t a buzz word but an essential part of staying alive. So we’re expanding what impact investment means to our current and future investors, to include education and advanced research outside our own company, and doing it in a very cost effective way through partnership within a genuinely world-leading consortium.

As a species we need to redefine our global relationship with our shared oceans and we can’t do that without a data driven discussion and intelligent real-world solutions. Passion does not solve problems on its own, but we’re really excited about being part of this incredible group.

You can read more about SuMMeR CDT here

Site Refit

The funding round earlier this year has enabled us to increase recycling capacity and make the site easier, more comfortable and safer to use. That refit is now almost complete but we are already seeing benefits in the quality and consistency of the products we ship.

Crucially we are now in a position to complete some product development towards closed loop manufacturing, a project we call R² Marine Nylon™, and progress a new material product line that includes recycled carbon fibre. We’ve been wanting to do this ‘forever’ but our site and processes needed strengthening first. When we talk to potential customers in 3DP they love the 100% recycled PA6-CF concept and always ask when they can test it. We’re working with both Loughborough University Design School and Exeter University Consulting to provide customers certainty that ‘greenwashing’ is not something that they should be worried about as far as Fishy Filaments’ products are concerned in this R&D program, building on previous work with both universities.

We can now also look towards lowering our operational carbon footprint by recycling our process water and the addition of renewable energy provision on site. These actions could potentially reduce our CO2-eq impact of an already impressive 2-3% of virgin PA6 by around a 3rd, but we will commision a new quantitative LCA to confirm that estimate when we have completed that work. These new supporting elements around the core process development work will also increase our understanding of the off-grid potential of our recycling process for global roll-out.

Wider Progress

We were delighted to be featured on a leading YouTuber’s stream about ‘Fish Friendly’ filaments in October. Zack Freedman has 255k subscribers and the video has racked up over 47,000 views so far. We noticed a definite spike in attention on our own online presence and its great that the non-industrial 3DP segment is seeing value in what we are doing.

I spoke with the CEO of the Cornish Fish Producer’s Organisation on an episode of The Fathom podcast, a fisheries industry focussed channel, to explain progress and potential future scenarios for plastics recycling in the industry. The Fathom has wide, UK-centred fishing industry listenership that spans both active fishers, processors and regulators and we have had some very positive direct responses along that spectrum of interests.

Our material featured in the winning entry into this year’s Vissla Creators and Innovators Upcycling Contest, a global competition that is in its 7th year and that has spawned some designs of surfcraft that gained global attention. Some readers may remember the designer, Niall Jones, from an earlier project we did with Falmouth University and the cold water surf brand, Finisterre.

We had a visit from The UK’s Marine Management Organisation, the MMO, as part of their fact finding tour of the Cornish fisheries sector hosted by the Cornish Fish Producers Organisation. The CEO, Tom McCormack, brought his management team and spent more than their planned time with us finding out about the transformative technology and economics that our net recycling technology can provide to UK and global fisheries.

Finally we have a raft of customer projects ongoing but that I can’t really talk about. However we believe that they will be transformative for the markets and the industry leaders that we’re working with.

To say that there is lots going on is an understatement and that isn’t even counting the new conversations arising from the recent visit to the Formnext trade show !

Ian

Founder/CEO, Fishy Filaments